Behind the Scenes | Custom Engineering and Plastic Mastery

What sets Midland Plastics apart is not only the quality of the materials we provide but also the depth of expertise behind them. Every sheet, rod, or tube we deliver can be shaped, cut, or engineered to exact specifications, thanks to our in-house team and advanced equipment.

When standard plastics are not enough, Midland’s custom fabrication and engineering services step in to create solutions that fit seamlessly into your operation.

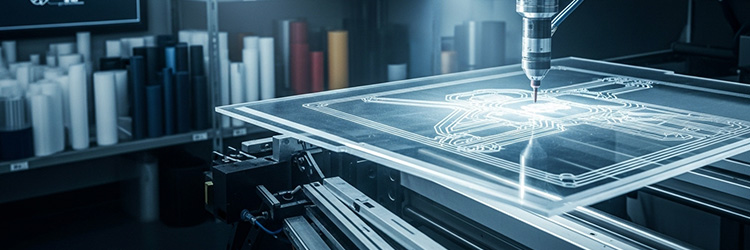

Precision Fabrication: Built for Your Needs

Our fabrication capabilities include cutting, bending, bonding, and finishing plastics to deliver parts that perform exactly as intended. Whether you need protective guards, machine components, or prototypes, Midland’s skilled technicians ensure every project meets high standards of quality and precision.

Explore our fabrication services

Machining: Accuracy That Drives Performance

Plastic machining requires specialized knowledge to get it right. With CNC technology and experienced operators, we machine everything from simple parts to complex geometries. This ensures consistency, durability, and cost-effectiveness across high-volume or specialized runs.

Thermoforming: Shaping Plastics into Possibility

Thermoforming transforms flat plastic sheets into custom shapes for protective covers, housings, functioning parts, and more. Midland’s thermoforming process gives you the flexibility to create lightweight yet strong components that can be scaled to fit your unique requirements.

Engineering Support: More Than Materials

Sometimes the challenge is not just about cutting or shaping plastic but solving a larger problem. Midland’s engineering team collaborates with clients to evaluate performance

requirements, select the right material, and design parts that meet exact tolerances. The result is a partnership that goes beyond supply and into innovation.

Why It Matters

From prototypes to production, Midland Plastics provides the knowledge and craftsmanship that bring ideas to life. Our ability to blend custom engineering with plastic mastery ensures that clients receive solutions built for performance, efficiency, and reliability.

“What makes Midland unique is not just the materials we provide, but the way we partner with customers. Our engineering team takes the time to understand real-world challenges and deliver solutions that make a measurable difference. That focus on service is why customers continue to trust Midland after more than 50 80 years.”

– Terry Stephens, Director of Sales & Marketing at Midland Plastics

Behind the scenes, this is the Midland difference: a team committed to making plastics work harder for every industry we serve.